Preparing for Shearing

These guidelines help ensure a safe, efficient and hygienic shearing process, while protecting the welfare of the sheep and the quality of the wool.

Advice on Controlling Parasites in Sheep

Many external parasites in UK sheep flocks are nearly invisible but can significantly impact health, welfare, and profitability. This manual helps farmers identify and control them effectively.

Visit AHDB SiteAdvice on How Best to Handle Sheep During Extreme Weather

With much of the country facing warm, dry conditions, it’s vital to consider heat’s impact on livestock. Here are AHDB’s top tips to prevent heat stress in sheep.

Visit AHDB SiteShearing Training

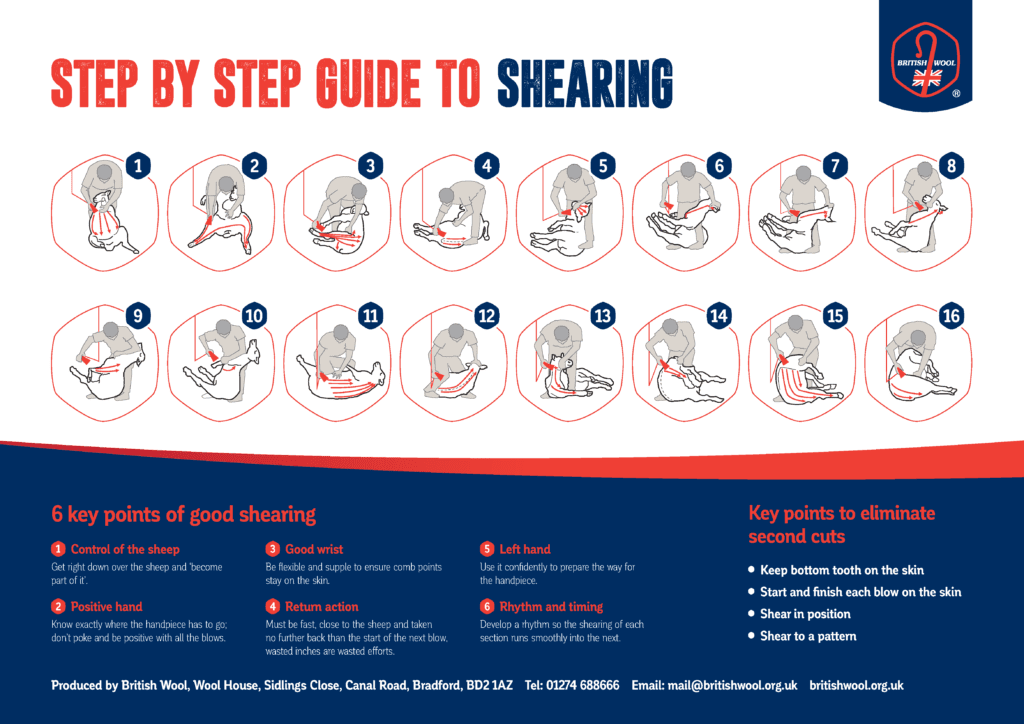

Explore British Wool’s shearing training courses designed to improve skills and promote high industry standards.

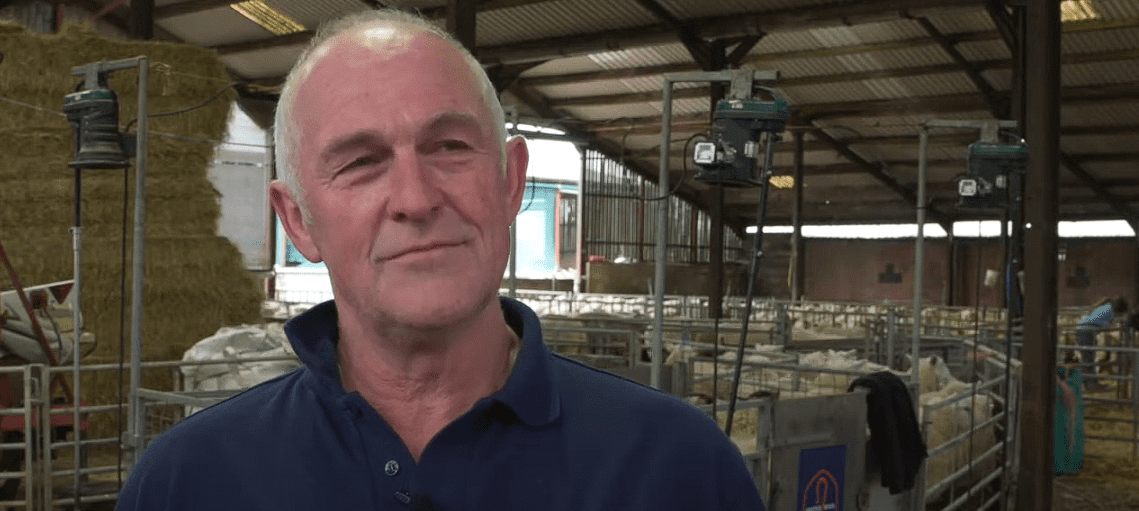

Shearing Top Tips with Alan Derryman

Alan Derryman is one of British Wool’s most experienced shearing training instructors. Listen to his top 5 tips for success in this short video.

YFC Shearing Course Offer

British Wool and the National Federation of Young Farmers’ Clubs (YFC) in England, Scotland and Wales are collaborating again this year to offer subsidized shearing training to YFC members.

For the seventh year in a row Young Farmers Club members affiliated to a YFC can take advantage of a 50% discount on British Wool Shearing Courses. The discounted offer applies to courses in machine and blade shearing.

British Wool’s two-day courses are held in all regions of the UK and cover the essentials of shearing. Attendees receive hands-on practical tuition in small groups, typically with a ratio of one instructor to four participants. This allows attendees to develop their technique as well as receiving guidance on animal welfare, the use of shearing equipment, and staying safe in the shearing shed. The discount applies to courses for absolute beginners, intermediate, and advanced level shearers. British Wool and the YFC actively encourage Young Farmers to improve their technique by attending further training.

The discounted price of £110 plus VAT is exclusively available to YFC members who register before the 31st of March 2025. British Wool’s courses are also available to non-members at £220 plus VAT which still represents excellent value for small group tuition.

Richard Schofield, Shearing Manager at British Wool, said:

“British Wool and the YFC have worked together now for several years in different projects. This incentive is the best so far giving members the opportunity to attend shearing courses with a 50% discount whilst you remain a YFC member enabling you to develop your shearing skills.”

Eligibility

Your YFC membership must be affiliated with one of the national federations of England, Scotland, or Wales to be eligible for the discounted courses.

Closing date: 31st March 2025

Statement on Animal Welfare

British Wool takes animal welfare extremely seriously. Whilst we do not have any powers to enforce animal welfare legislation, if we are made aware of any cases of animal mistreatment, we will inform the agencies who have such responsibility, (Defra, Farm Animal Welfare Committee (FAWC), the RSPCA (England & Wales), SSPCA (Scotland) and ISPCA (Northern Ireland)).

The Animal Welfare Act 2006 and its detailed subsidiary guidelines, The Welfare of Farmed Animals (England) Regulations 2007, prescribe the high animal welfare standards that English farmers are required to meet. Similar legislation exists for the other UK countries:

Welfare of Farmed Animals Regulations (Northern Ireland) 2012

The Welfare of Farmed Animals (Wales) Regulations 2007

The Welfare of Farmed Animals (Scotland) Regulations 2010)

We also commissioned a study called ‘Best Management Practices’ to give the industry a comprehensive summary of the husbandry, health and environmental standards under which British Wool is produced.

In global terms, UK sheep farms are small, having on average approximately 350 sheep. UK sheep are raised naturally outdoors on pasture. As a result, the scale and method of UK lamb production is such that it is not considered an ‘intensive’ farming activity by animal welfare campaigning bodies.

Sheep are required to be shorn of their wool once a year for their own comfort and health. Hence, wool is a naturally occurring by-product.

Every year British Wool puts over 850 people in all parts of the UK through our two day shearing training courses that are tailored to their existing level of experience and skill. It goes without saying that shearing in accordance with best practice industry standards ensures that the process is stress free for the animals.